The takeoff calculation is arguably the most complex type of

computation, involving numerous considerations.

We meticulously examine each step to deliver the most precise

result available for your flight simulation experience.

The take-off phase spans from brake release to either the point

where the airplane reaches 1500 feet or the height necessary to

clear the last take-off obstacle if it's higher.

-

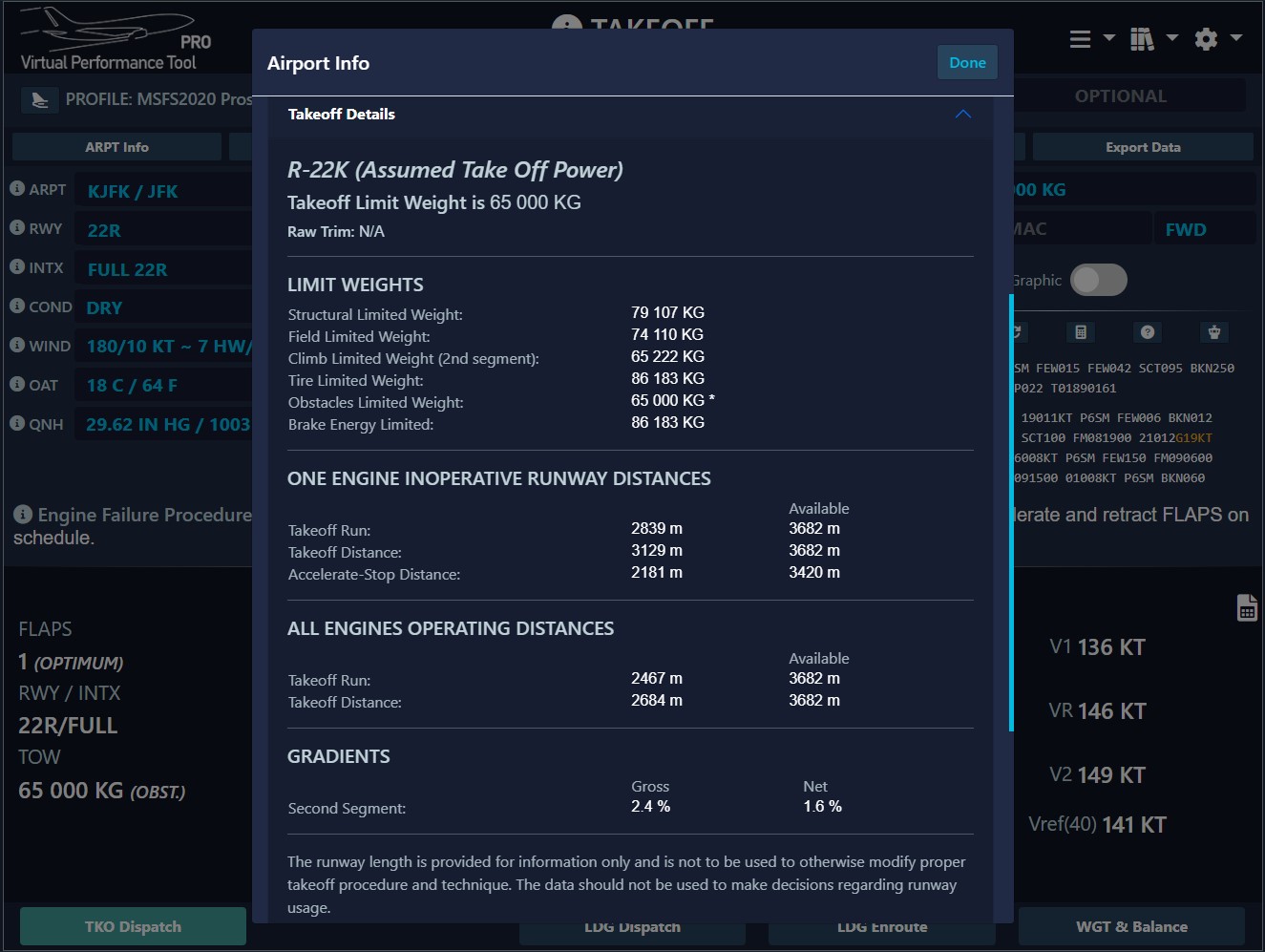

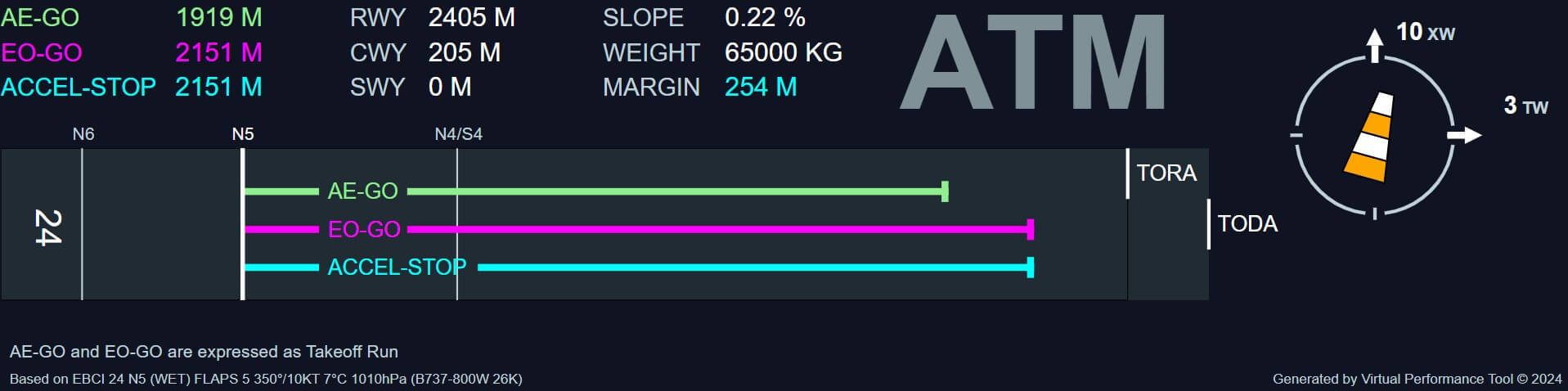

Field Length:

Ensures adequate runway for safe continuation or rejection of

takeoff in the event of an engine failure, and sufficient runway

for a normal, all-engines takeoff.

Take-off distance is determined between the start of the

take-off roll and the point when the airplane reaches 35 ft (15

ft on wet).

The engine failure is considered to take place at VEF

and to be recognized (action taken) at V1.

If decision at V1 is to continue, a take-off distance

is defined by the airplane having reached a height of 35 ft (15

ft on wet).

If decision at V1 is to stop, an accelerate-stop

distance (ASD) is then defined.

The safety margin consists in adding 15 % to the distance

demonstrated by flight test.

-

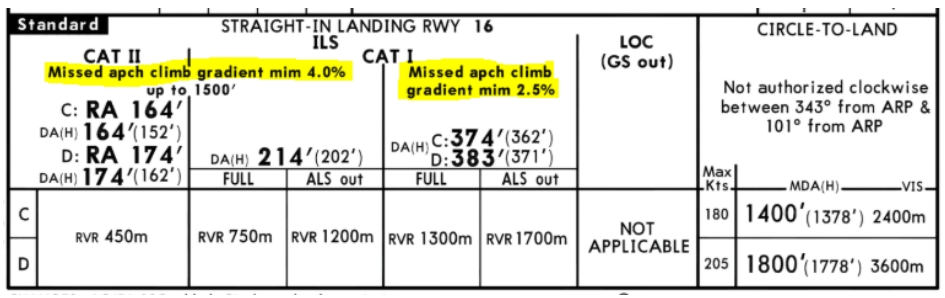

Minimum Climb Requirement (One Engine Inoperative):

Ensures the aircraft has sufficient climb capability throughout

takeoff.

Includes the required limitations to the take-off weight in

order to achieve minimum climb performance. It is worth noting

that, at this stage, those minimum performances have nothing to

do with the obstacle clearance criteria. The obstacle clearance

will be treated separately and may, of course, lead to higher

performance penalties.

The minimum climb gradient criteria correspond to still air

conditions, while the obstacle clearance takes the wind into

account.

The takeoff is divided into four sections, each with a minimum

climb gradient required for certification, up to an altitude of

1500 feet. This gradient is solely dependent on the number of

engines the aircraft is equipped with.

-

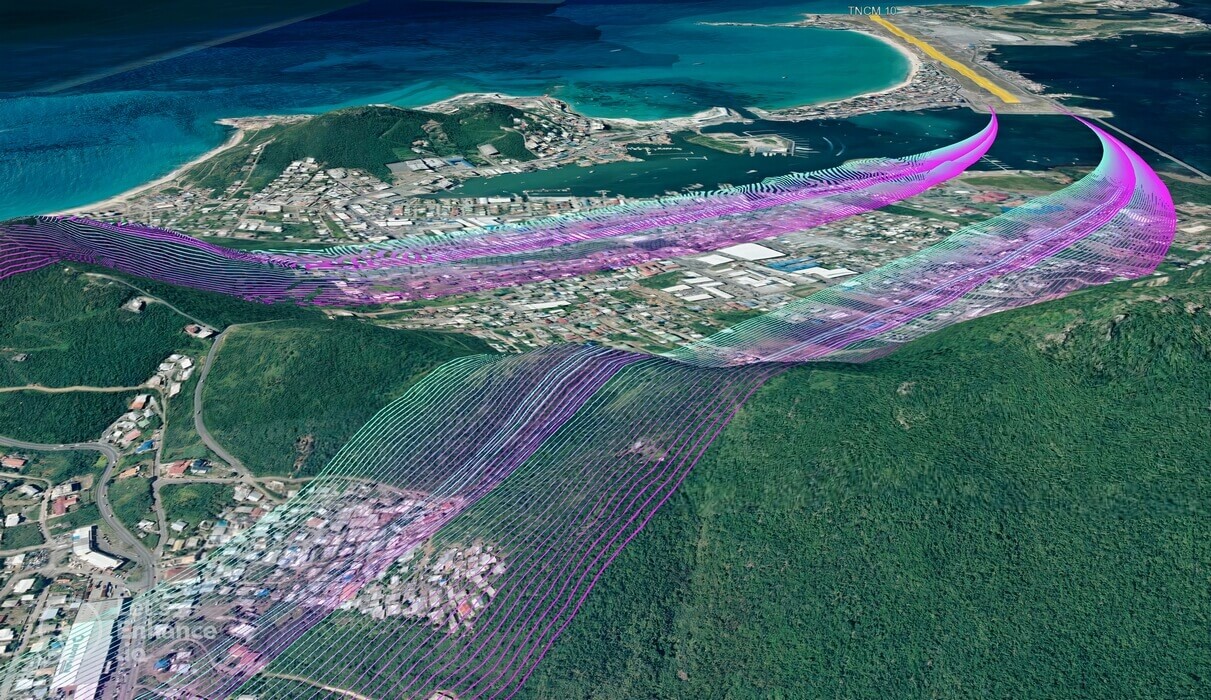

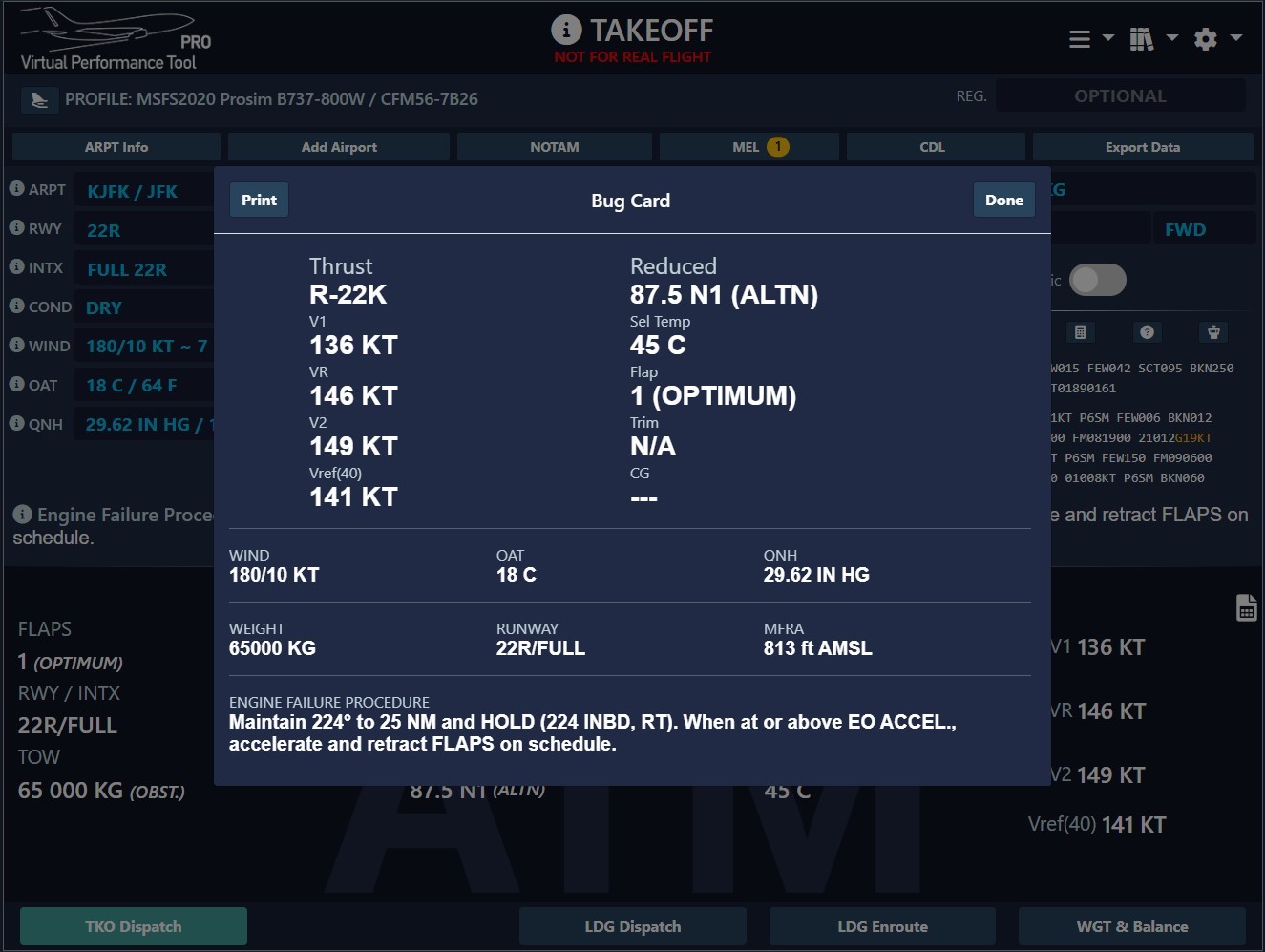

Obstacle Clearance Requirement:

Ensures the aircraft can clear all obstacles with the required

margin, and this is precisely where the

Engine Failure Procedure can have a significant

impact.

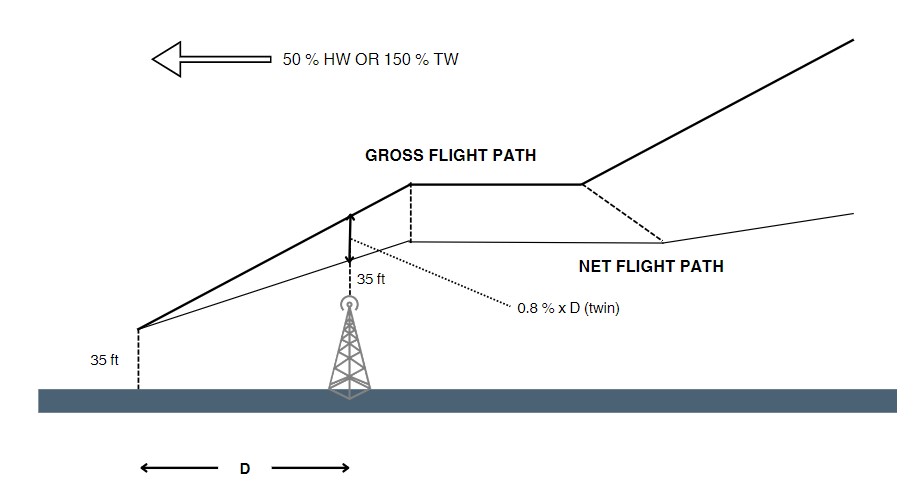

For obstacle clearance, a NET flight path must be taken into

account. This trajectory is virtual, achieved by reducing the

gross trajectories with a safety margin determined based on the

number of engines the aircraft possesses.

Furthermore, the winds used in the obstacle clearance computation

represent 50 % of the actual HW and 150 % of the actual TW

(airport wind).

Finally, the so computed net flight path must overfly the

obstacles by at least 35 ft.

-

Maximum Certified Tire Speed:

Limits the maximum ground speed before liftoff.

Tires are designed for a maximum ground speed. Its limiting effect

will be applicable for all T/O speeds up to VLOF.

Tire speed requirements have been checked and are not limiting for

normal conditions. However, these limits could be exceeded at

certain conditions where improved climb is used in conjunction

with downhill slope, tailwind, and/or high altitudes and

temperatures.

-

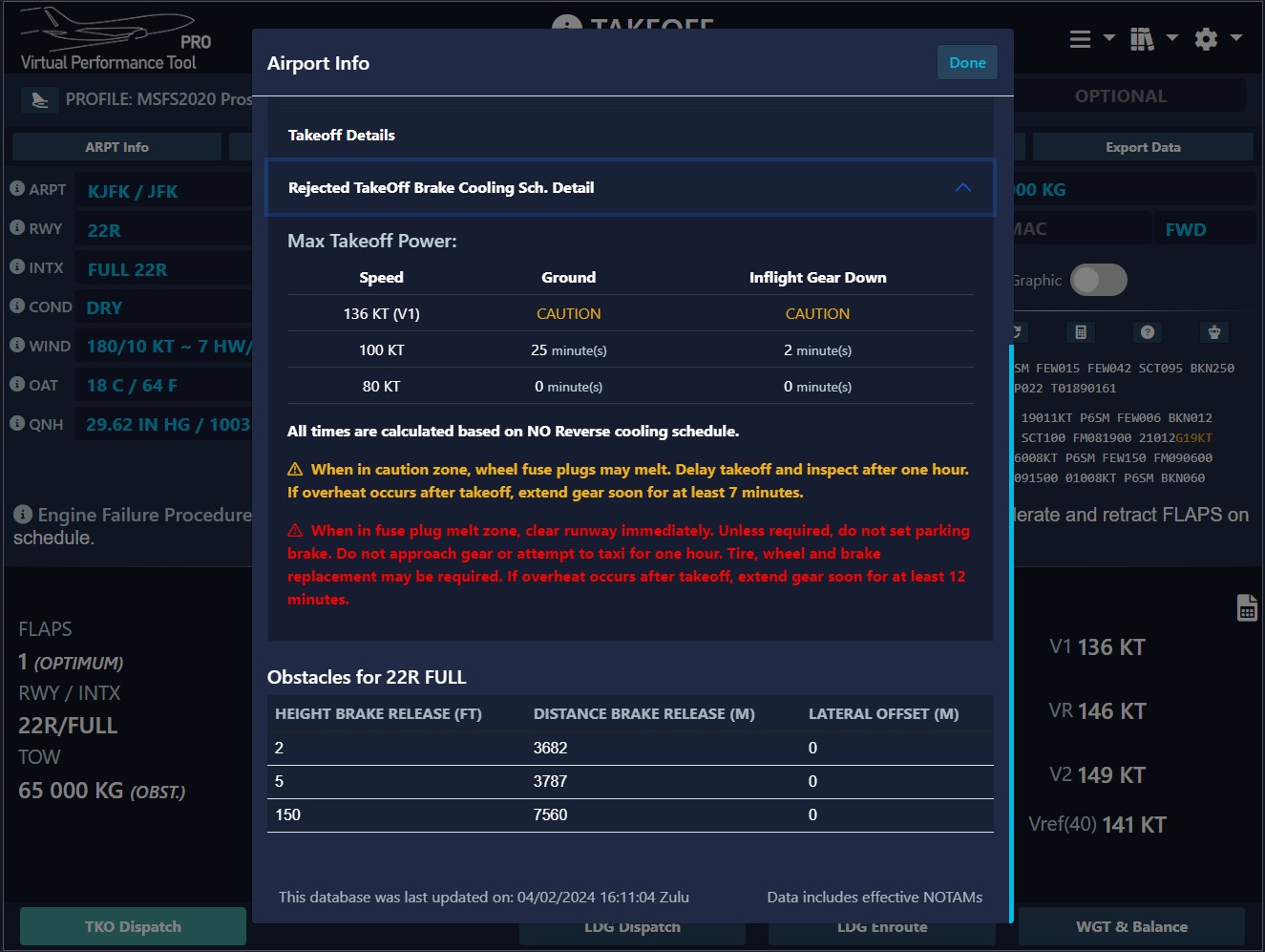

Brake Energy Requirement:

Sets the maximum amount of energy the brakes can absorb in the

event of a rejected takeoff.

Maximum brake energy absorption is limited by design and

certification.

VMBE (Maximum Brake Energy Speed) is the speed giving

a kinetic energy which is equal to the maximum brake energy.

V1 must never exceed VMBE. Should V1

exceed VMBE, weight must be reduced, or the analysis

must be done again with another flap setting or a lower

V1/VR.

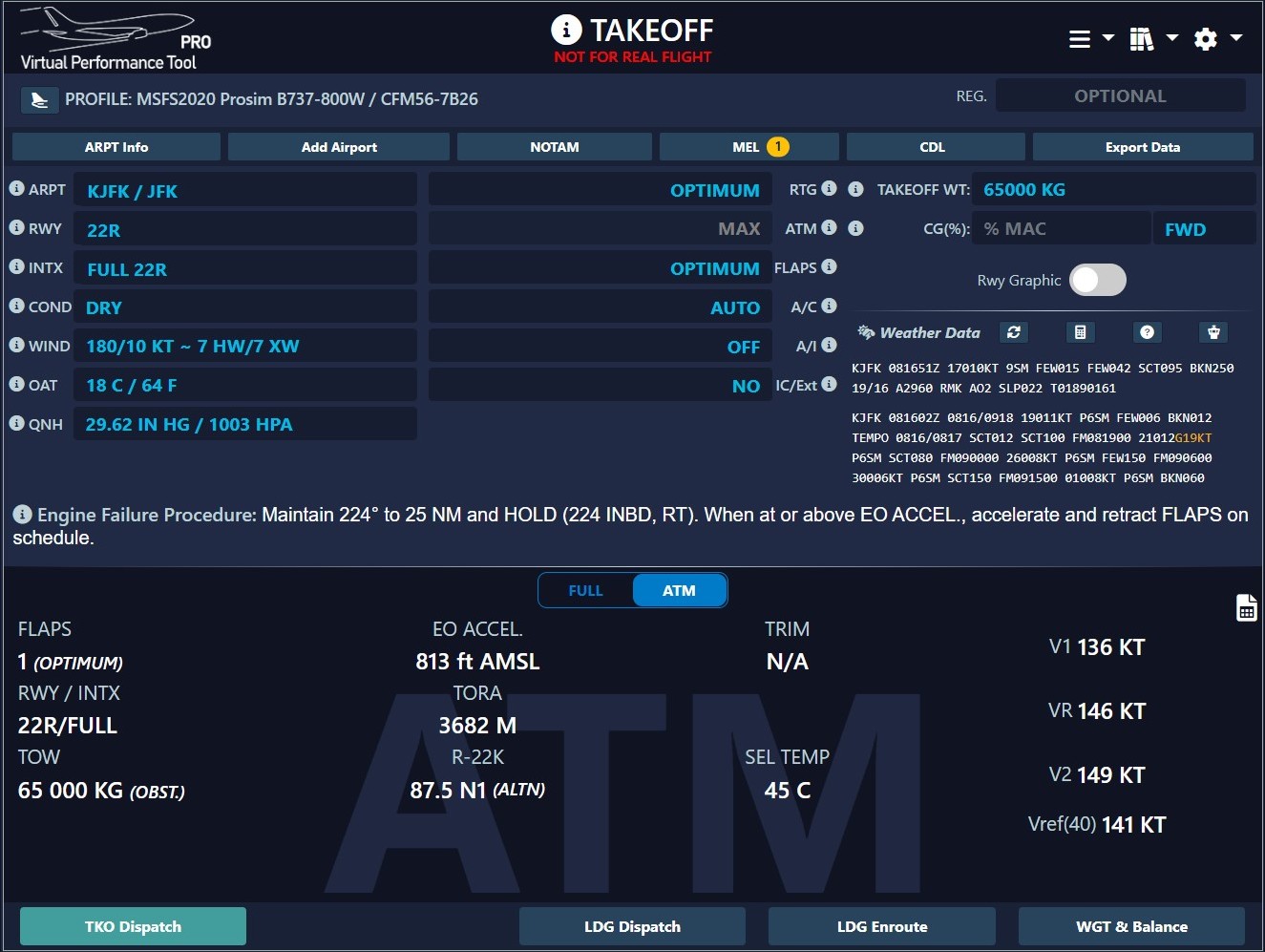

Optimum V1

V1 is the latest speed at which you can safely abort a takeoff, and

it's also the earliest speed at which you can proceed with the

departure.

However, fewer virtual pilots are aware that V1 actually

represents a range of speeds, typically set between:

The operator has the flexibility to configure their performance tool

according to their procedures. This includes selecting the preferred

value of V1 to be used.

-

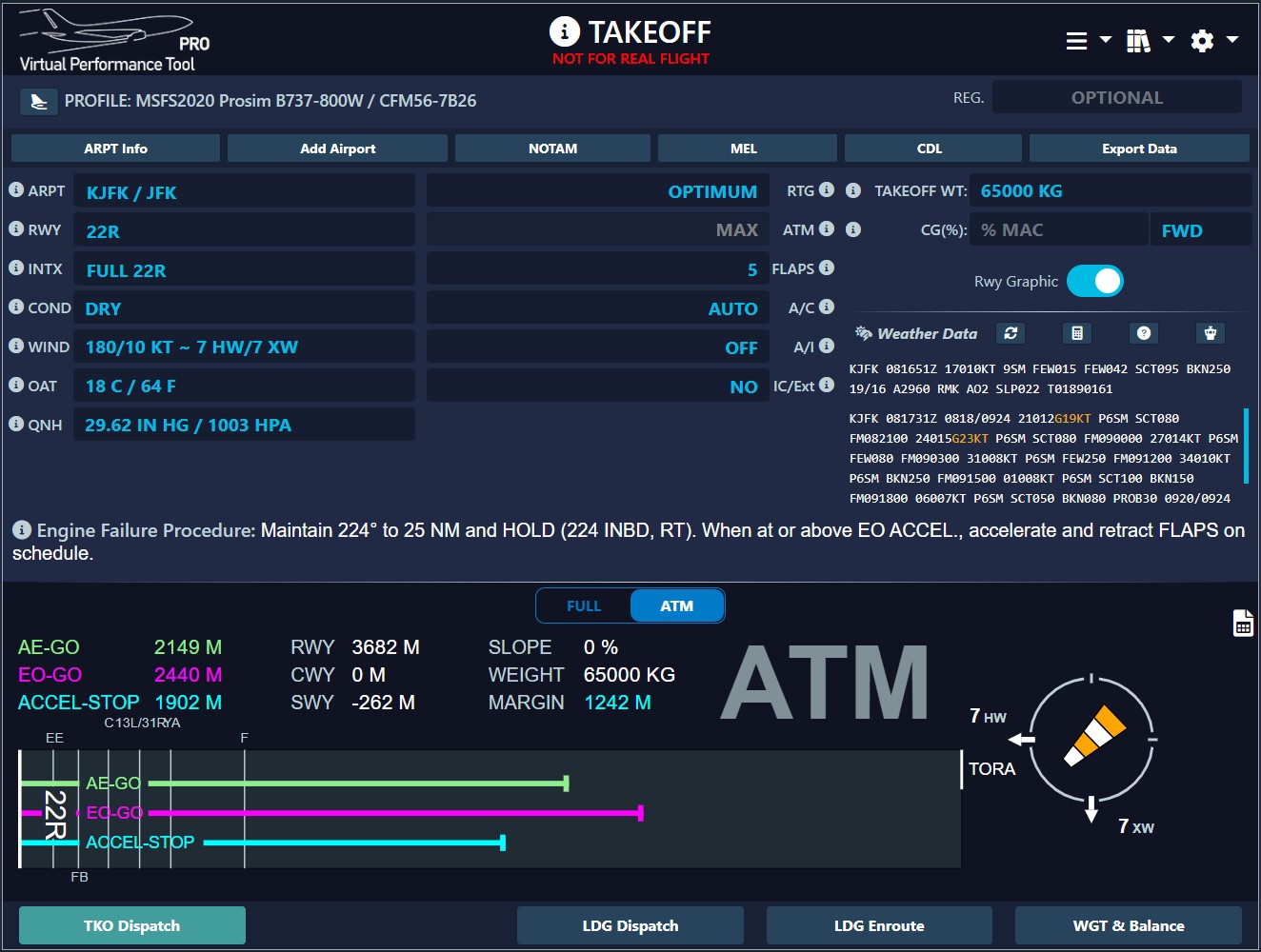

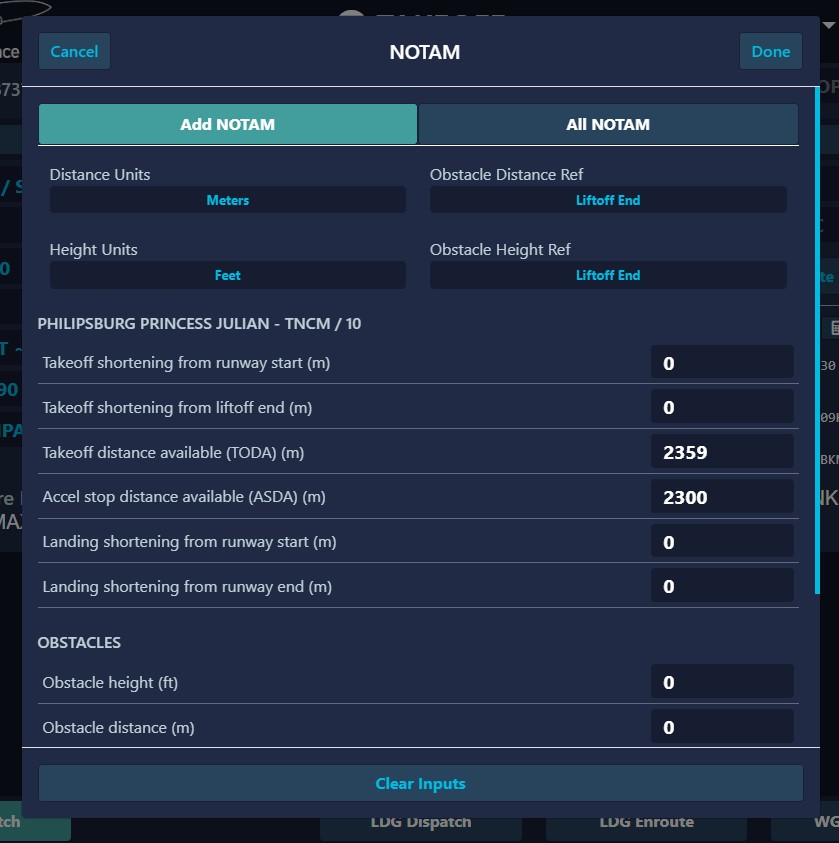

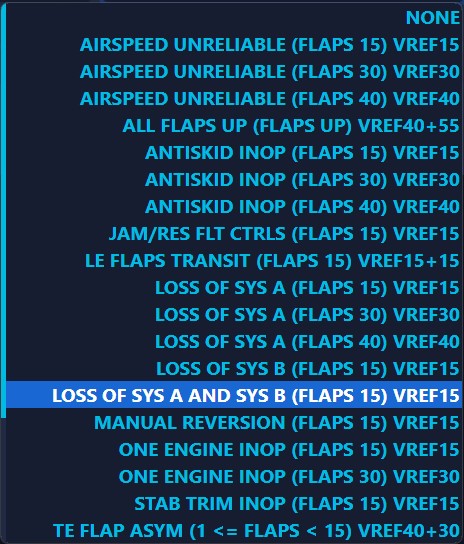

Minimum V1: the minimum permissible V1 speed for the referenced

conditions from which the takeoff can be safely completed after

the critical engine has failed at the designated speed

(VEF). This option prioritizes shorter ASDR

(Accelerate-Stop Distance Required) but results in a longer

Engine-Out Go distance. Due to the smaller V1, it is

typically more inclined towards a "stop" decision during takeoff.

-

Maximum V1: the maximum possible V1 for the referenced

conditions at which a rejected takeoff can be initiated and the

aircraft stopped within the remaining runway (or runway plus

stopway where available). This option prioritizes a shorter

Engine-Out Go distance but results in a longer ASDR

(Accelerate-Stop Distance Required). Due to the larger

V1, it is typically more inclined towards a "go"

decision during takeoff. This is usually the closest one to

the CDU speeds.

-

Optimum V1: a flexible and optimized V1 that balances the

requirements of Takeoff Distance Required (TODR) and

Accelerate-Stop Distance Required (ASDR). It considers factors

such as wind, slope, and obstacle clearances to deliver the most

effective performance available.

-

V1 to achieve the highest possible performance

limited weight

-

Unbalance for clearway and stopway of unequal usable lengths

- Unbalance for lineup distances of unequal lengths

-

Unbalance to meet V1MCG and VR

requirements

-

Unbalance to meet brake energy (VMBE) and obstacle

clearance requirements

- May not be compatible with FMC or QRH takeoff speeds

-

If a range of V1 is available, the balanced V1

will be shown in the output if it is within the range. If the

balanced V1 is not within the range, then either

the minimum V1 or the maximum V1 will be

shown, whichever is closer to the balanced V1.

Our tool is set to provide you with the

Optimum V1 for your

conditions, which may differ from the generic values given by your

CDU/MCDU. Understanding the theory will help you to maximize your

performances.

A reliable performance tool offers insights beyond the capabilities

of your aircraft's CDU/MCDU. Therefore, it's crucial to question any

discrepancies and

prioritize the outcomes provided by your performance tool.

We currently do not provide customization options for the V1

calculation method. However, this feature may be developed at a

later stage.

Improved Climb

The "Improved Climb" technique uses the excess runway available to

accelerate to higher takeoff speeds thereby achieving higher

gradient capability.

The excess gradient is achieved by using a heigher V2. To increase

V2:

- VR (rotation speed) must be increased

-

V1 must be increased to ensure sufficient speed is available to

continue the takeoff in case of engine failure

The excess speed must be cautiously managed, especially on very long

runways and at high weights, as your Performance-Limited Takeoff

Weight (PLTOW) could be restricted by tire limits. A rejected

takeoff at such speed and weight may lead to fuse plug melting.

This limitation can be realistically assessed using our

performance tool.

As per definition, the Improved Climb technique uses extra speed to

gain in climb performances. When this technique is available, the

Vspeed displayed by the CDU/MCDU

will NOT match the VPT calculations because there

is no "Improved Climb option". This is normal and realistic. You are

expected to utilize the results from your performance tool to

implement this technique.

Extended Second Segment

Typically, a standard Acceleration Height is determined in

accordance with operator procedures, with a legal minimum starting

point as low as 400 ft AGL. However, opting for too low an

acceleration height may pose conflicts with certain obstacles,

limiting your maximum takeoff weight. Conversely, selecting an

excessively high acceleration height may clash with engine

limitations.

The Maximum Takeoff Thrust (TOGA) is certified for use within a

maximum window of 5 minutes, extendable to 10 minutes with

manufacturer authorization. While this enhanced feature requires

additional maintenance considerations, it can significantly boost

performance, especially in scenarios with high obstacles surounding

the airport of departure.

Our premium package provides diverse profiles with various engine

certifications, allowing you to tailor your choice to specific needs

and optimize performance. This process is automatically reflected in

your Engine Out Acceleration Height / Minimum Flaps Retraction

Altitude.

Loss of Runway Length due to Alignment

Airplanes typically enter the takeoff runway from an intersecting

taxiway. The airplane must be turned so that it is pointed down the

runway in the direction for takeoff. FAA regulations do not

explicitly require airplane operators to take into account the

runway distance used to align the airplane on the runway for

takeoff. On the contrary, EASA regulations require such a distance

to be considered.

At Virtual Performance Tool, we

conduct lineup corrections as part of our takeoff performance

calculations whenever the runway configuration prevents positioning

the airplane at the threshold. This adjustment is typically

necessary for a 90° taxiway entry or a 180° turnaround on the

runway. Detailed adjustments, as outlined in published tables, guide

this correction process.

Slippery vs Friction

Here's a fun fact you can explore with our

precise tool: A shallow layer of dry

snow can actually create a slippery runway surface, leading to an

increase in the Accelerate-Stop Distance Required (ASDR). However,

once the snow depth reaches a certain threshold, the accumulated

contaminant will induce friction, thereby reducing the ASDR.

Consequently, it's common to observe a lower Performance-Limited

Takeoff Weight (PLTOW) on runways with shallow snow depths compared

to those with deeper accumulations.